Semiconducteurs SiC : Delphi Technologies s’allie à l’Américain Cree

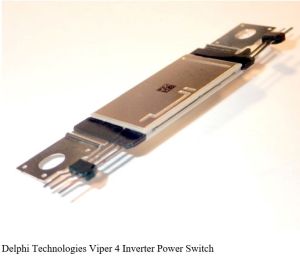

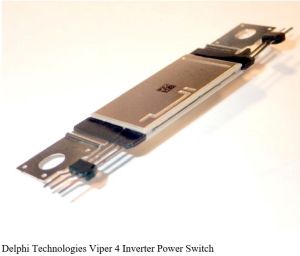

L’équipementier automobile britannique Delphi Technologies et l’Américain Cree, chef de file des semiconducteurs SiC, annoncent un partenariat visant à utiliser la technologie des dispositifs à semiconducteurs en carbure de silicium afin de créer des systèmes électroniques plus rapides, plus petits, plus légers et plus puissants pour les futurs véhicules électriques (EV). Les MOSFET en carbure de silicium Cree seront initialement utilisés dans les onduleurs 800 volts de Delphi Technologies. La production démarrera en 2022.

Delphi Technologies, a global provider of automotive propulsion technologies, and Cree, a leader in silicon carbide semiconductors, announce a partnership to utilize silicon carbide semiconductor device technology to enable faster, smaller, lighter and more powerful electronic systems for future electric vehicles (EV).

Delphi Technologies, a global provider of automotive propulsion technologies, and Cree, a leader in silicon carbide semiconductors, announce a partnership to utilize silicon carbide semiconductor device technology to enable faster, smaller, lighter and more powerful electronic systems for future electric vehicles (EV).

Cree is committed to leading the global transition from silicon to silicon carbide and recently announced silicon carbide capacity expansion to generate up to a 30-fold increase in capacity. The company offers a comprehensive set of silicon carbide and GaN (Gallium nitride) power and RF (radio frequency) solutions through its Wolfspeed business unit.

Cree’s silicon carbide-based MOSFET (metal–oxide–semiconductor field-effect transistor) technology coupled with Delphi Technologies’ traction drive inverters, DC/DC converters and chargers will extend driving range and deliver faster charging times of EVs, while also lowering weight, conserving space and reducing cost. The Cree silicon carbide MOSFETs will initially be used in Delphi Technologies’ 800 Volt inverters for a premium global automaker. Production will ramp in 2022.

“Delphi Technologies is committed to providing pioneering solutions to vehicle manufacturers,” said Richard F. (Rick) Dauch, CEO of Delphi Technologies. “Our collaboration with Cree will create a significant benefit to automakers as they work to balance meeting stricter global emissions regulations with consumer appetite for electric vehicles. Overcoming driver anxiety related to electric vehicle range, charging times and cost will be a boon for the industry.”

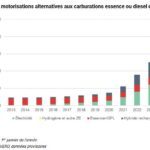

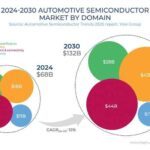

The adoption of silicon carbide-based power solutions is rapidly growing across the automotive market as the industry seeks to accelerate its move from internal combustion engines to EVs. IHS estimates that, by 2030, 30 million high voltage electrified light vehicles will be sold representing 27 percent of all vehicles sold annually. Inverters are one of the highest-value electrification components and their efficiency has an industry-changing impact on many aspects of vehicle performance.

“Cree’s technology is at the heart of the dramatic change underway in EVs, and we are committed to supporting the automotive industry as it transitions from silicon-based designs to more efficient, higher performing silicon carbide solutions,” said Gregg Lowe, CEO of Cree. “This partnership with Delphi Technologies will help drive the adoption of silicon carbide in the automotive sector. As the world leader in silicon carbide, Cree is continuing to expand capacity to meet market demands with our industry-leading power MOSFETs to help achieve a new, more efficient future.”

Delphi Technologies’ new silicon carbide inverter operating at 800 Volts will provide vehicle engineers with additional flexibility to optimize other powertrain systems. Options include more range or a smaller battery; ultra-fast charging or smaller, lighter, cheaper cables; and greater harvesting of vehicle kinetic energy when braking, further extending vehicle range.

Delphi Technologies offers solutions for internal combustion engine, hybrid and electric passenger cars and commercial vehicles. Headquartered in London (UK), the company operates technical centers, manufacturing sites, and customer support service centers in 24 countries and employs more than 21,000 people around the world.